CS#4: Innovative landfill leachate treatment to enable resource recovery from wastewater treatment plants, Ancona & Sofia

Partners: UNI VPM, UNI Sofia, KWB

Our aim: Developing an innovative approach to treat landfill leachate

If landfill leachate with high PFAS loading reaches municipal wastewater treatment plants (WWTPs), no proper treatment is possible, which prevents a zero-pollution discharge and thus further water reuse. Therefore, PFAS contaminated sewage sludge and reverse osmosis (RO) concentrate are currently transported to incineration plants or hazardous waste landfills for disposal.

However, these practices are not sustainable, do not avoid the spreading of PFAS into the environment and do not aim to recover resources.

Case Study 4 tested innovative technological solutions aimed at obtaining a near zero pollution discharge from landfill leachate and to enable a safe resource recovery. For this purpose, membrane filtration, co-pyrolysis, and plasma treatments were tested in existing full-scale landfill leachate treatment plants in Italy and Bulgaria.

An initial investigation of the fate of PFAS in conventional landfill leachate treatment plants helped to identify potential contamination pathways to the environment and to plan corrective actions. Hence, to provide effective and sustainable barriers for the spread of PFAS, innovative and advanced technological solutions were tested. Landfill leachate was treated by RO and nanofiltration (NF) at pilot scale to assess the environmental and economic sustainability of different membrane technologies to remove PFAS. To treat sewage sludge and leachate concentrate, pyrolysis and plasma processes had been tested.

Potential energy recovery has been evaluated through the valorisation of Bio-oil and Syngas produced by Pyrolysis.

Conclusion

In Bulgaria, various laboratory scale non-thermal plasma systems operating at atmospheric pressure were developed and applied for the treatment of landfill leachate and model solutions containing different PFAS substances (PFOA, PFBA, PFDA, PFHxA, PFPeA) and with varying concentrations. The plasma systems tested include the DBD (dielectric barrier discharge) with liquid electrode, the underwater diaphragm discharge, the MW (microwave) plasma torch (in continuous flow and batch modes), the Surfaguide plasma source and, specially designed at UNISOFIA lab, the Beta plasma device (in continuous flow and batch modes). The plasma characteristics of different plasma sources can vary widely, leading to very different results in PFAS degradation.

All plasma devices show high effectiveness in long-chain PFAS compounds degradation (from 40 % to > 90 % depending on the plasma source). Only one plasma device (the Beta device) displayed similar degradation amounts of short-chain PFAS as for long-chain PFAS.

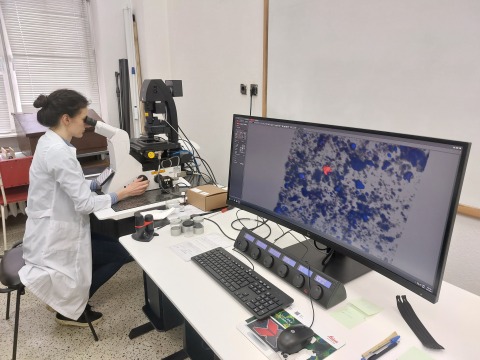

A new method for assessment of impaired biological activity and toxicity based on fluorescent staining and digital image analyses was developed and applied for detection of complex toxicity of leachate and assessment of impaired biological activity of sludge/membrane concentrates during landfill leachate treatment. Based on the created method for assessing the toxicity of landfill leachates, mathematical relationships between toxicity and PFOA concentration as a model PFAS representative have been derived.

The results obtained and analysed with the fluorescence method show that treatment with various plasma sources reduces the toxicity of the infiltrate and the infiltrate spiked with PFAS which depends on both the concentration of PFAS and the type of plasma treatment.

As an effect of plasma treatment, the long-chain PFAS are transformed to shorter-chain substances. This results in higher concentrations of shorter-chain PFAS and detection of “new” PFAS substances (by-products which were not in the initial solutions). The toxicity of these short-chain by-products is lower than the toxicity of the long-chain PFAS substances which is a good explanation for the toxicity reduction and the positive effects of plasma treatment.

At higher concentration of PFAS in model solutions, both higher degradation rate during plasma treatment and higher toxicity reduction are observed which demonstrates a good correlation between the toxicity reduction and PFAS degradation. These results correlate well also with PFAS CALUX results, especially for PFDA. The PFAS-CALUX analyses demonstrated a significant reduction of toxicity after plasma treatment with surfaguide (49.5 % reduction for a model solution with 100 µg/L PFOA and 78 % reduction for the solution with 100 µg/L PFDA); beta-device treatment reduced the toxicity by 84 % for PFDA but only by 4 % for PFOA solution. The better performance for PFDA reduction is consistent with the data from the fluorescence assays, where over 60 % toxicity reduction is recorded at the same concentrations.

In Italy, we conducted several mass flow studies for PFAS compounds in three full-scale leachate treatment plants (LTPs), which showed that almost the entire load of PFAS measured in the influent landfill leachate remained in the liquid phase after conventional treatments (i.e., coagulation/flocculation, biological treatment, ultrafiltration). Advanced treatment such as RO was able to remove PFAS from the liquid stream and to produce a PFAS free permeate. Nevertheless, the need of appropriate technologies for treating RO concentrates to remove PFAS resulted evident for a safe discharge of this waste stream.

At the LTP of Jesi (Ancona, Italy), we installed a membrane pilot system, which was operated in the NF/RO double stage configuration (Figure 1). Data on PFAS removal and on economical/environmental costs to treat leachate were obtained. Pilot tests data was also used later for a Life Cycle Assessment study.

Finally, we have performed thermochemical (pyrolysis) tests at different temperatures and residence times to remove PFAS from the waste produced at Jesi LTP, which are sludge and RO concentrate. A stack-emission treatment line was installed to recover bio-oil and to characterize syngas (Figure 2). Data had been collected about PFAS destruction and the possibility for energy recovery.

The results showed high effectiveness of pyrolysis in the destruction of PFAS in LTP sludge even when it was mixed with highly contaminated RO concentrate (Co-Pyrolysis). The treatment of LTP effluent using membrane filtration, then the treatment of LTP sludge with the concentrate from the membrane created a closed loop providing good solution for PFAS treatment in Landfill leachate.

A comparison between (Membrane filtration + Pyrolysis) & (Membrane filtration + Incineration) was done by analysing Life Cycle Assessment (LCA). The results showed good advantage in the use of Pyrolysis compared to incineration in terms of energy production and flexibility as it could be moved and installed directly at the plant. In addition, systems using NF had lower electrical energy consumption than systems using RO.

%20quer.png)

%20zusammen.png)